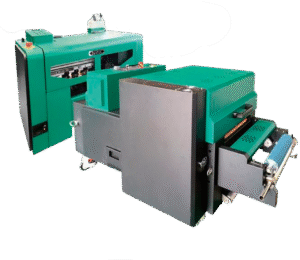

Plotter UV 3040

Descripción

Description

Printhead: Epson 13200-U1 HD Printhead

Number of Printheads: 1

Printing Speed: 0.28 m²/h ~ 3 m²/h

Print Width:

Platform: 297 x 420 mm Drum: 230 x 420 mm

Media Thickness: 1 mm ~ 90 mm

Ink Type: Environmentally Friendly UV Curing Ink

Color Configuration: Standard: CMYK+W+V Optional: YMCK LC LM+W

RIP Software: Maintop/Flexiprint/RIIN

Printing Media: Glass, plates, various signs, crystal, PVC, acrylic, plastic leather, etc.

Photo Format: TIFF, JPEG, PDF, EPS, PNG, AI, BMP, etc.

Computer Configuration: Windows 10/64-bit System

Transmission Interface: Gigabit Ethernet port, 500GB hard drive or larger

Voltage/Rated Power: 220V 50Hz/60Hz 500W

Operating Environment: Temperature: 18°C~28°C, Humidity: 40%~60%

Machine Size/Weight: 1020*830*615mm, 114kg

Packaging Size/Weight: 1130*910*760mm, 124kg

Textile/Rigid Compatibility

Acrylic

PVC/Forex

Polycarbonate

MDF and varnished wood

Aluminum/Painted sheet metal

Glass (clean and degreased)

Rigid cardboard/Foam board

PS/PET/Rigid plastics in general

-

SPEED

0.28 m²/h - 3 m²/h -

MEDIA

Glass, plates, various signs, crystal...

- Daily Power On and Circulation Even if you're not printing, turn it on every day to circulate the UV ink and prevent it from hardening inside the printhead.

- Cleaning the Wiper, Cap Station, and Surrounding Area Do this daily. UV ink is thicker and crusts up quickly, clogging the nozzles.

- Avoid Direct Light on the Ink UV inks are cured by light. Keep the cartridges and the plotter area away from sunlight or external UV lights.

- Nozzle Check 1–2 Times a Day UV ink tends to dry faster. You detect any cuts before they affect a job.

- Manual printhead cleaning (only when necessary) Do this with UV cleaning solution and a lint-free cloth. Never use alcohol.

- Proper ventilation of the work area UV inks emit fumes. A well-ventilated environment improves the life of the equipment and the health of the operator.

Related Products

-

2 cabezales Epson I1600Maintenance

- Dust-free environment Keep the working environment dust-free to prevent it from affecting printing.

- Temperature and humidity The machine should operate at a temperature of 25–30°C and with a humidity of 40–60%.

- Platform cleaning Keep the entire printer tidy and clean, removing dust from friction areas.

- Cleaning the bottom of the printhead Move the carriage to the cleaning position, wipe the bottom of the printhead with a non woven cloth dampened with cleaning fluid or distilled water, removing dirt from the printhead and nearby areas.

Max width: 300mmSpeed: 7.1 m2/hMedia: Pet Film 320mmRequest a quote -

8 cabezales Epson I3200

- HIGH-RESOLUTION PRINTHEAD 8 Epson I3200-A1 printheads; 1-pass speed can reach up to 320 m²/h.

- SMART LOW-INK ALARM Reduces the need to frequently check remaining ink levels and reminds you to add ink in time to ensure continuous printing workflow.

- STABLE MEDIA FEEDING AND TAKE-UP SYSTEM Convenient and fast; media is quickly loaded, equipped with automatic paper measurement and anti-scratch function. If the consumables deform, printing stops automatically to prevent head strikes.

- ADVANCED CAPPING STATION Equipped with an advanced intelligent printhead cleaning and moisturizing system, providing safe and convenient maintenance and cleaning functions with simpler operation.

- SPECIALLY DESIGNED CARRIAGE The printhead position can be adjusted according to different printing media, with anti-collision devices on both sides.

- SMART HOT-AIR DRYER The intelligent drying system is synchronized with printing. Temperature can be adjusted in real-time during the printing process.

- FLUORORUBBER PRESSURE ROLLER The U.S. fluororubber pressure roller prevents static electricity. The exclusive lifting device compensates for partial paper bulging during the printing process.

- HIGH-PRECISION PLATFORM The printing platform is controlled within ±7.5 wires and features hard oxidation treatment on the surface to prevent long-term deformation.

- THK SILENT GUIDE RAIL Uses Japanese THK silent linear guide rail for smoother movement and longer service life.

- LEADSHINE SERVO MOTOR The bidirectional brushless Leadshine motor offers higher precision, lower length deviation, and more stable performance.

- LARGE-CAPACITY INK TANKS Four 3L large-capacity ink tanks supply ink independently and continuously.

- IGUS INK CHAIN FROM GERMANY High-quality IGUS ink chain imported from Germany, ensuring excellent printing performance.

- COMPATIBILITY Win 7 / Win 8 / Win 10.

- Daily power-on (even if you don't print) Helps the inks circulate and prevents bubbles from forming or drying out in the heads.

- Automatic cleaning activated Let the equipment do its maintenance cycle. Do not interrupt it: it prolongs the life of the head.

- Keep the capping station, dampers, and wiper clean These consumables accumulate ink and lint. A weekly cleaning prevents stains and clogs.

- Control the ambient humidity Ideal: 45%–60%. Low humidity dries the ink; high humidity generates droplets on the paper.

- Check feed rollers and trays If they are dirty, they mark the paper or generate banding.

- Use the equipment at least 3–4 times per week Sublimation plotters need constant ink movement.

Max width: 1900mmSpeed: 320 m²/hMedia: Thermal transfer paperRequest a quote -

6 cabezales Epson I3200

- High Speed 6-printhead design; maximum achievable speed is 32 m²/h.

- White-Ink Circulation System Prevents white-ink clogging and ensures more stable printing.

- Robust Body Japanese steel guide rail; integrated high-strength stand.

- Built-in Air Purifier Powder agitator with fume-purification function, electronic cleaner, and oil-fume separation.

- Intelligent Printhead Plate Heating The head heats automatically according to temperature to achieve uniform printing.

- Smart Touchscreen Easier operation thanks to the touch control panel.

Compatibility: Standard PhotoPrint and others.

Maintenance- Dust-Free Environment Keep the work environment dust-free to prevent it from affecting printing.

- Temperature and Humidity The machine should operate at a temperature of **25-30°C** and with a humidity of **40-60%**.

- Platform Cleaning Keep the entire printer tidy and clean, removing dust from friction areas.

- Cleaning the Underside of the Printhead Move the carriage to the cleaning position, clean the underside of the printhead with a **non-woven cloth dampened with cleaning fluid or distilled water**, removing dirt from the printhead and surrounding areas.

Max width: 600mmSpeed: 36 m2/hMedia: Pet film 600Request a quote -

3 cabezales Epson I3200

-

- HIGH-PRECISION PRINT HEAD 3 Epson I3200-A1 print heads, 2-pass speed can reach up to 120㎡/h.

- ADVANCED CAPPING STATION Equipped with an advanced intelligent automatic print head cleaning and moisturizing device, which can pump ink well and maintain fluent ink flow.

- INTELLIGENT LACK OF INK ALARM Reduces the tediousness of frequently checking the remaining ink quantity, and at the same time, reminds you to add ink in time to ensure the continuity of the printing job.

- INTELLIGENT MIST PRINTING AND VSDT PRINTING The unique intelligent two-dimensional mist and wave-mist function, and VSDT variable droplet technology, obviously improve the printing quality.

- STABLE MEDIA FEEDING AND TAKE-UP SYSTEM Convenient and fast, printing media is quickly stored, equipped with automatic paper measurement and anti-rubbing function; if consumables are deformed, the printing automatically stops to prevent scratching the print head.

- WIDE APPLICATION With the help of the heat transfer machine, the printed images can be transferred to many different non-elastic materials, such as polyester, chiffon, silk, and flags. There is no limit to the patterns, making it a good choice in the field of decoration, clothing, and advertising.

- SPECIALLY DESIGNED CARRIAGE The position of the print head can be adjusted according to different printing media and anti-collision devices on both ends to give the print head more comprehensive safety protection.

- THK SILENCE GUIDE RAIL Using the imported Japanese THK silent linear guide rail to effectively reduce resistance and noise during the printer's operation.

- LARGE CAPACITY INK TANKS Four units of 3L large-capacity ink tanks provide ink independently and continuously, ensuring the long-term continuity of ink output.

- INTELLIGENT HOT AIR DRYER The intelligent integrated air and heat dryer, two-stage heating, middle hot air, and intelligent start-stop technology ensure drying performance and greater energy savings at the same time.

- LEADSHINE CHINESE MOTOR The Leadshine two-way brushless motor has higher precision, smaller length error, and more stable performance.

- IGUS INK CHAIN FROM GERMANY High-quality IGUS ink chain imported from Germany, to ensure the good completion of the printing work.

- FLUORINATED RUBBER PINCH ROLLER The US fluorinated rubber pinch roller prevents static electricity from flying ink, prints more accurately, and avoids wrinkles.

- TWO-LEVEL INK SUPPLY SYSTEM Adopts a two-level ink supply system that allows continuous printing for a long time to ensure the image output quality.

- COMPATIBILITY Win 7 / Win 8 / Win 10.

-

- Daily power-on (even if you don't print) Helps the inks circulate and prevents bubbles from forming or drying out in the heads.

- Automatic cleaning activated Let the equipment do its maintenance cycle. Do not interrupt it: it prolongs the life of the head.

- Keep the capping station, dampers, and wiper clean These consumables accumulate ink and lint. A weekly cleaning prevents stains and clogs.

- Control the ambient humidity Ideal: 45%–60%. Low humidity dries the ink; high humidity generates droplets on the paper.

- Check feed rollers and trays If they are dirty, they mark the paper or generate banding.

- Use the equipment at least 3–4 times per week Sublimation plotters need constant ink movement.

Max width: 1900Speed: 120 m²/hMedia: Transfer paperRequest a quote -