What is DTF textile printing and how does it work?

DTF (Direct To Film) printing allows you to transfer designs onto fabrics using heat and a special film. It is a versatile and cost-effective alternative to DTG, screen printing, and sublimation, and is compatible with various types of fabric.

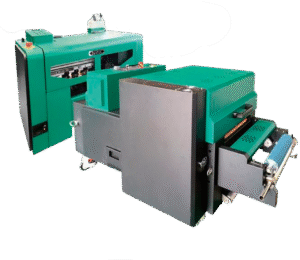

Our products

-

6 cabezales Epson I3200Max width: 600mmSpeed: 36 m2/hMedia: Pet film 600Request a quote

-

2 cabezales Epson I3200Max width: 600mmSpeed: 10 m2/hMedia: Pet Film 620mmRequest a quote

-

4 cabezales Epson I3200Max width: 600mmSpeed: 20 m2/hMedia: Pet Film 620mmRequest a quote

-

2 cabezales Epson I3200Max width: 600mmSpeed: 9 m2/hMedia: Pet Film 620mmRequest a quote

-

4 cabezales Epson I3200Max width: 600mmSpeed: 23 m2/hMedia: Pet Film 620mmRequest a quote