4 cabezales Epson I3200

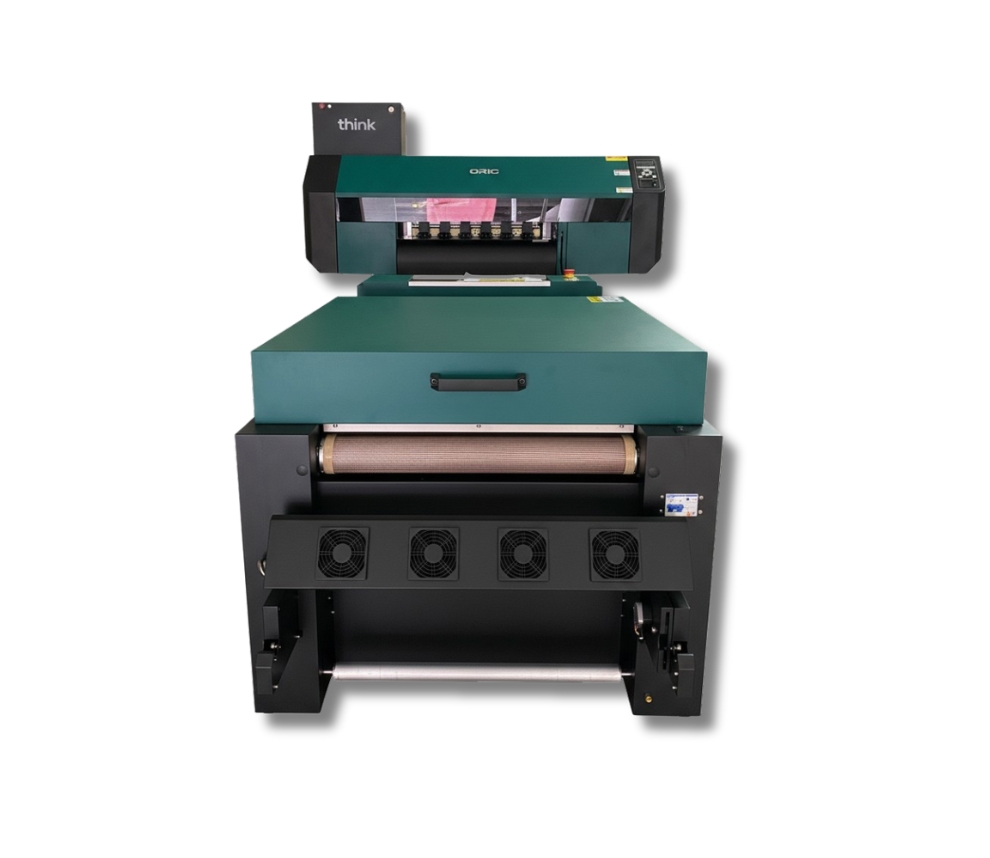

ORIC 60 CM 4 Printheads

Descripción

Description

Maximum print width: 600 mm

Maximum speed: 20 m²/h

Compatible media: 620-mm PET film

Number of printheads: 4

Software compatibility: Maintop / PhotoPrint / Riprint

Textile Compatibility/Rigid Fabrics:

100% Cotton

100% Polyester

Cotton/Polyester Blends

Lycra – Elastane

Fleece – Rustic – Jersey

Sports Fabrics

Dark, Light, and Brightly Colored Fabrics

Denim / Jean

TNT (Non-woven Fabric)

Leatherette and Some Flexible Synthetics

Maintenance

- Dust-Free Environment Keep the work environment dust-free to prevent it from affecting printing.

- Temperature and Humidity The machine should operate at a temperature of 25–30°C and a humidity of 40–60%.

- Platform Cleaning Keep the entire printer tidy and clean, removing dust from friction areas.

- Cleaning the Underside of the Printhead Move the carriage to the cleaning position, clean the underside of the printhead with a non-woven cloth dampened with cleaning fluid or distilled water, removing dirt from the printhead and surrounding areas.

Related Products

-

2 cabezales Epson I1600Maintenance

- Dust-free environment Keep the working environment dust-free to prevent it from affecting printing.

- Temperature and humidity The machine should operate at a temperature of 25–30°C and with a humidity of 40–60%.

- Platform cleaning Keep the entire printer tidy and clean, removing dust from friction areas.

- Cleaning the bottom of the printhead Move the carriage to the cleaning position, wipe the bottom of the printhead with a non woven cloth dampened with cleaning fluid or distilled water, removing dirt from the printhead and nearby areas.

Max width: 300mmSpeed: 7.1 m2/hMedia: Pet Film 320mmRequest a quote -

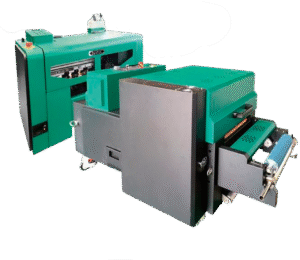

2 cabezales Epson I3200

- Maintenance Dust-Free Environment Keep the work environment dust-free to prevent it from affecting printing.

- Temperature and Humidity The machine should operate at a temperature of 25–30°C and a humidity of 40–60%.

- Platform Cleaning Keep the entire printer tidy and clean, removing dust from friction areas.

- Cleaning the Underside of the Printhead Move the carriage to the cleaning position, clean the underside of the printhead with a non-woven cloth dampened with cleaning fluid or distilled water, removing dirt from the printhead and surrounding areas.

Max width: 600mmSpeed: 10 m2/hMedia: Pet Film 620mmRequest a quote -

6 cabezales Epson I3200

- High Speed 6-printhead design; maximum achievable speed is 32 m²/h.

- White-Ink Circulation System Prevents white-ink clogging and ensures more stable printing.

- Robust Body Japanese steel guide rail; integrated high-strength stand.

- Built-in Air Purifier Powder agitator with fume-purification function, electronic cleaner, and oil-fume separation.

- Intelligent Printhead Plate Heating The head heats automatically according to temperature to achieve uniform printing.

- Smart Touchscreen Easier operation thanks to the touch control panel.

Compatibility: Standard PhotoPrint and others.

Maintenance- Dust-Free Environment Keep the work environment dust-free to prevent it from affecting printing.

- Temperature and Humidity The machine should operate at a temperature of **25-30°C** and with a humidity of **40-60%**.

- Platform Cleaning Keep the entire printer tidy and clean, removing dust from friction areas.

- Cleaning the Underside of the Printhead Move the carriage to the cleaning position, clean the underside of the printhead with a **non-woven cloth dampened with cleaning fluid or distilled water**, removing dirt from the printhead and surrounding areas.

Max width: 600mmSpeed: 36 m2/hMedia: Pet film 600Request a quote -

15 cabezales Epson I3200

- PRINTER 15 heads

- PRINTING SPEED 1 pass 610 m²/h

- PRINT WIDTH 1900 mm

- COMPATIBLE MEDIA Heat transfer paper

- COMPATIBILITY Win 7 (64 bit) / Win 10 (64 bit)

-

- Daily power-on (even if you don't print) Helps the inks circulate and prevents bubbles from forming or drying out in the heads.

- Automatic cleaning activated Let the equipment do its maintenance cycle. Do not interrupt it: it prolongs the life of the head.

- Keep the capping station, dampers, and wiper clean These consumables accumulate ink and lint. A weekly cleaning prevents stains and clogs.

- Control the ambient humidity Ideal: 45%–60%. Low humidity dries the ink; high humidity generates droplets on the paper.

- Check feed rollers and trays If they are dirty, they mark the paper or generate banding.

- Use the equipment at least 3–4 times per week Sublimation plotters need constant ink movement.

Max width: 1900mmSpeed: 610 m²/hMedia: Thermal Transfer PaperRequest a quote